Jade Engineered Plastics has grown, invested in the East Bay

From a 600-square-foot building in Bristol to its new 66,000-square-foot facility in Warren, Jade Engineered Plastics has shown that prosperous, local manufacturing is still alive on the East Bay.

This item is available in full to subscribers.

Please log in to continue |

Register to post eventsIf you'd like to post an event to our calendar, you can create a free account by clicking here. Note that free accounts do not have access to our subscriber-only content. |

Day pass subscribers

Are you a day pass subscriber who needs to log in? Click here to continue.

Jade Engineered Plastics has grown, invested in the East Bay

Steve Holland, the second-generation president of Jade Engineered Plastics, proudly walked through the 66,000 square-foot facility, nestled off the beaten path of Route 136 in Warren, like the late Gene Wilder strolled through his infamous candy factory in Mel Stuart’s 1971 fan-favorite.

He warmly greeted each worker he came across, teased his office manager of 29 years for her insistence on riding a motorcycle despite her age, and lovingly described the process by which the plant conjures its teflon-based plastic parts for its approximately 400 customers around the nation — the same process that his father used when the company started with just three employees (including himself) in a 600-square-foot room in Bristol 46 years ago.

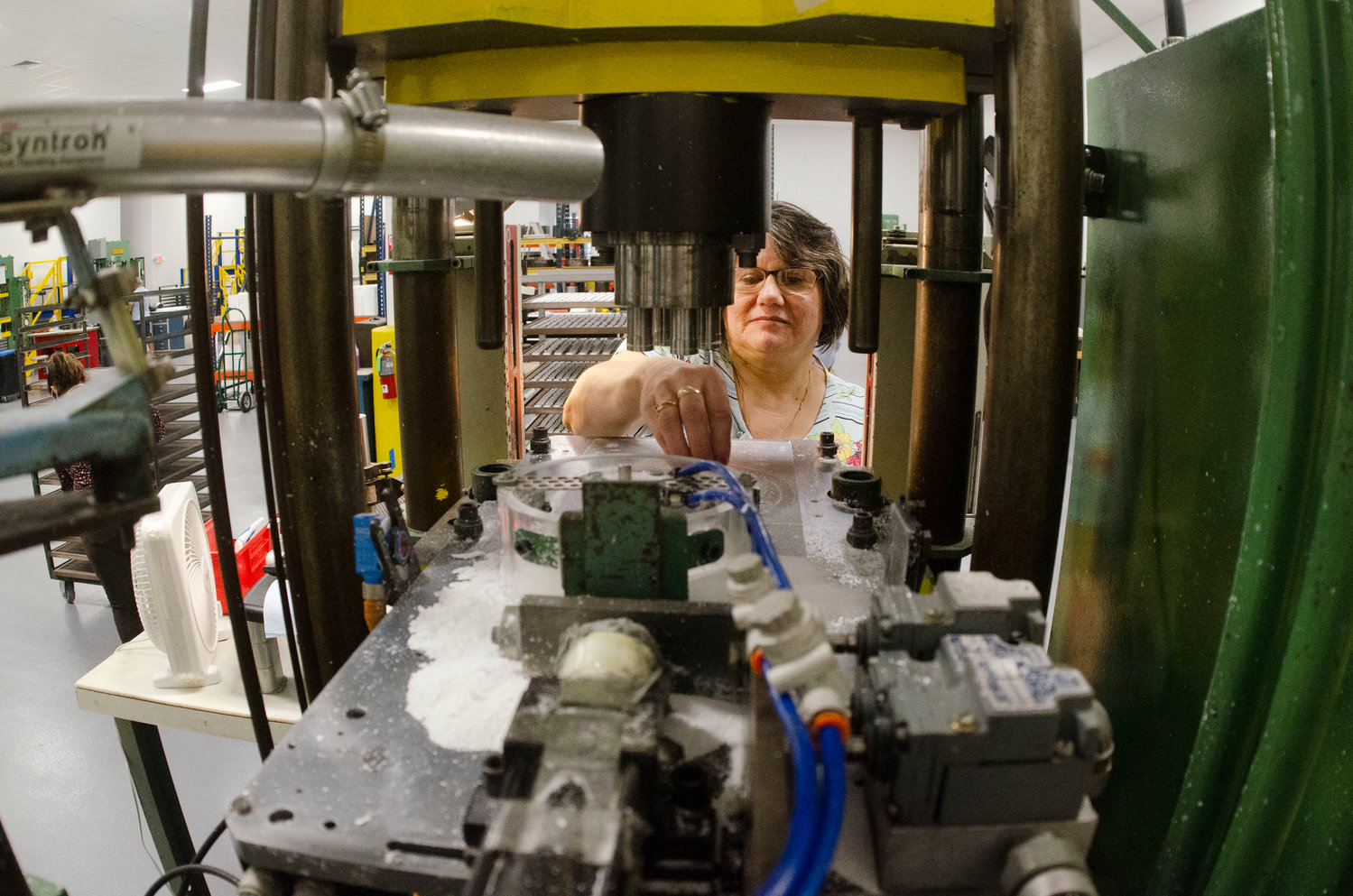

They take raw teflon powder resin, squash it together via machines into pre-designed molds under intense pressure, bake it at 700 degrees Fahrenheit and then, one cool, lathe it and craft it to fit the customer’s priorities. Surgically slicing off sharp burrs that result from cutting the plastic, done entirely by hand, ensures a smooth finish. What you’re left with is a resilient, frictionless piece of material that can be used in everything from bathroom appliances to cutting edge biotechnical cancer research.

“Uses like you can’t imagine,” he said. “There’s a ton of teflon in automobiles, planes, trains, heavy duty construction equipment.” He adds that the plastic can be utilized in applications like kitchen faucets over the course of millions of repetitions without ever needing to be replaced.

Steady growth, and a bright future

Jade has seen steady growth over its nearly 50 years. As of this week, they employ 96 employees in a range of positions, from office staff to machine operators and custodians, and the six women who work to de-bur hundreds of thousands of parts each year. The company acquired its first CNC lathe in 1984 (which still runs today), and now has 40 such machines.

The pristine facility at 15 New Industrial Way has allowed the company’s output to increase significantly, and 2021 will be a record year in terms of their production, Holland said. But it didn’t happen overnight.

“We’ve evolved over the years,” Holland said. “We’ve had quite an opportunity. I don’t think anybody would have ever thought we’d be here today.”

Beginning in Bristol, the company doubled its 600 square feet to 1,200 before upsizing again in 1987 to its location on Broad Common Road, which gave them 10,000 square feet. They expanded that facility in 1992 and maintained their growing customer base until last year, when they finally outgrew the building.

“We were at a point where we couldn’t go any further,” Holland said. “We couldn’t produce any more product in there.”

And so began the project to purchase and rehabilitate the massive warehouse in Warren, which was formerly a distribution warehouse for FedEx. Considering the precise nature of Jade’s machining, they needed to refinish the floors and reconstruct nearly the entire building. It also just so happened that they took on the massive project right at the precipice of the COVID-19 pandemic in early 2020.

But despite the challenges, and a few close calls involving subcontractors fearing they had fallen ill with the virus, Jade was able to completely overhaul the building in six months, and move all their machinery into the building from their Bristol facility in just six weeks — while losing only four days of production time total.

“The last machine was still running the last day that we moved it,” Holland said. “It was running that morning and it was running again that afternoon.”

Although he admits that he didn’t draw it up this way on purpose, the ability to design their new facility in the midst of a pandemic provided Holland the opportunity to ensure that workers would be safe in light of the new health concerns.

“Now everybody has their own work space more than six feet apart,” he said. “It wasn’t a planned thing, but it worked out amazingly well.”

Community partner

With its long history in Bristol, and its new chapter beginning in Warren, Holland said that maintaining a role as a positive community partner remains important to Jade. In their first year at their new facility, they agreed to provide some land to the Warren Community Land Trust to create the Haile Farm Preserve walking trail.

“We plan on being around,” Holland said, adding that the third and fourth generations of his family are already working for, or are poised to be working for, the family business. “We gotta be a good neighbor.”

Holland said during the facilities tour that he was interested in opening up the plant to high school students some time by the end of October, which is recognized as National Manufacturing Month, to hopefully inspire a new generation of machinists and trade workers.

“Because if you don’t show them what’s out here, they won’t know,” he said.

Their work has resulted in Jade being recognized for an “Excellence in Business Award” given by the East Bay Chamber of Commerce at its annual banquet, to be held at the Ramada Banquet and Conference Center on Thursday, Oct. 21.